Maintenance Block

A feature called the Maintenance Block in the EMS (Enterprise Management System) assists businesses in conveniently monitoring and controlling maintenance of equipment/machinery and infrastructure. Combined with a modern ERP system, it makes all the maintenance processes planned, tracked, and documented to minimize downtimes, maximize equipment life, and hence lower repair expenses. Using enterprise resource planning, an organization can automate preventative maintenance, optimize and facilitate repair, and enhance the reliability of assets.

Top brands that use our platform

What is Maintenance Block?

The EMS (Enterprise Management System) Maintenance Block is a specific module aimed at maintaining the condition of equipment, machinery, and infrastructure of a given organization. It can be used to schedule, track, and perform maintenance activities in an efficient manner to minimize downtime and increase the lifetime of assets in order to maximize cost savings using a strong ERP system. Enterprise resource planning keeps maintenance records, enhances the performance of its assets, and also ensures that there is compliance with the operational standards.

Key Features

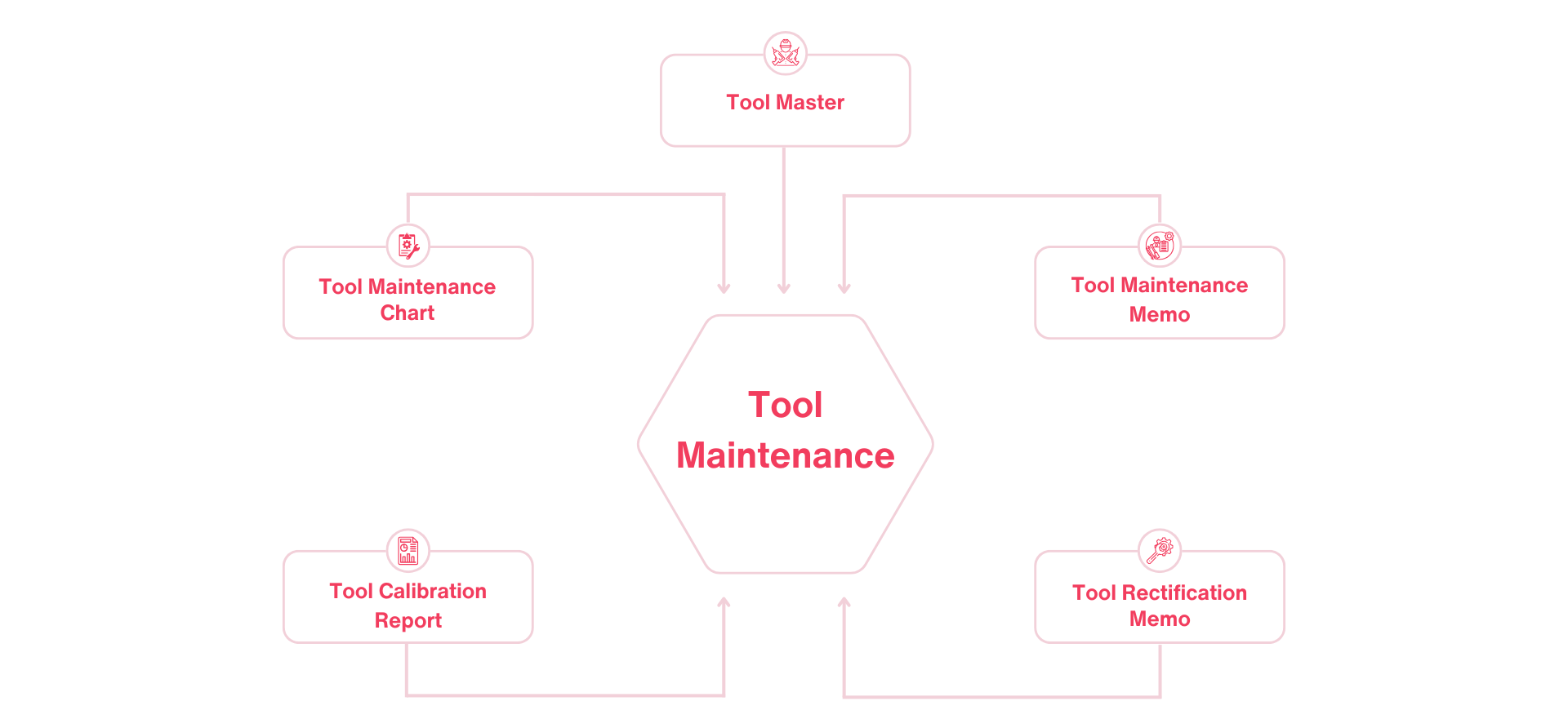

Tool Maintenance

The Tool Maintenance option within the EMS Maintenance Block assists companies that need to maintain the maintenance and repair of tools and equipment. It guarantees that the instruments are serviced, calibrated, and repaired, which facilitates effectiveness in operations and increases their life. ERP Interface gives correct scheduling, service history, and active alerts for maintenance.

Machine Maintenance Management

The Machine Maintenance Management feature makes the maintenance of machinery and production equipment easy in businesses. The Maintenance Block allows the company to avoid unforeseen failures, prolong machine usage, and cut repair expenses by means of automatic scheduling and tracking in the enterprise resource planning environment.

Machine repair and rectification tracking

This aspect enables companies to monitor the repair and correction of machines progressively. Leveraging the EMS Maintenance Block allows the tracking of all repair procedures and their analysis to reduce maintenance gaps and ensure that similar cases do not happen again. The ERP system package will integrate the repair history, and even the performance improvement will now be transparent.

Instrument Calibration Request & Approval

The instrument Calibration Request & Approval feature simplifies scheduling and authorization of instrument calibration. In the enterprise management system, it keeps the system on calibration activities, prompt, acceptable, and on the standards of the industry, facilitated by enterprise resource planning of automating the processes.

Instrument calibration reporting

The feature will give detailed reports on compliance, calibration status, and performance. The EMS Maintenance Block allows organizations to have a proper record of calibrations and, through the functions available in the ERP software, to analyze and enhance the efficiency of the calibrations.

Instruments repair & Rectification tracking

The Instrument Repair & Rectification Tracking facilitation assists businesses in controlling and tracking the instrument repairs. Its integration with the ERP system will make sure that the activities of repairs are tracked, analyzed, and optimized in terms of operational accuracy within the system of enterprise management system.

this is how Maintenance Block works