Production Planning Block

Our Production Planning Module will facilitate smooth production activities, as it becomes part of your ERP and enterprise management system with a view to total operational efficiency. This type of production planning reduces the work involved and allows a business to undertake the management of equipment and reduce activity layoffs. Our production planning module provides absolute accuracy and efficiency throughout the manufacturing process, all the way from demand planning to realization.

Top brands that use our platform

What is Production Planning Block?

Production Planning Block within an ERP system, such as Hexbis enterprise management system, is a systematic structure that makes optimal use of the whole flow of production. This is a production planning system that assists a business in planning manufacturing operations as well as handling resources available in such a way that production is efficient, gets delivered on time, waste is reduced, and production expenditure is minimized. When you integrate the production planning module into your ERP system, you can see, in real time, what is going on, have greater control, and use data to drive effective decisions to increase productivity.

Key Features

Production based on Route Card

Our production planning module has the Route Card-Based Production feature, which defines the orderliness of the manufacturing process as it monitors all levels of production. Built into the enterprise management system, it provides complete visibility of work orders, resource assignment, and workflow status, thereby allowing businesses to enhance the efficiency of their production planning system.

Rejection Handling

Our production planning module has a strong option of Rejection Handling that helps to handle poor, out-of-format, or damaged material in the course of the production, procurement, or dispatch. Part of the ERP, it ensures quality standards, reduces losses, and enhances the performance of suppliers and production.

Job worker Production

Our module of production planning eases outsourced production by the use of the Jobworker Production feature. It tracks work orders of jobs, materials dispatched to specific job workers, and integrates with inventory and financial systems by means of areas of enterprise management to realize inexpensive subcontracting in the production planning system.

Production Traceability

The Production Traceability Module in EMS ensures end-to-end tracking of materials, components, and finished products throughout the manufacturing process. This feature enhances quality control, compliance, and accountability, helping businesses minimize errors and recalls.

Routecard Status

In the production planning module Route Card status feature enables real-time information on manufacturing status. Enterprises can have an absolute view of the work processes, uncover bottlenecks, and streamline processes all in the enterprise management infrastructure, which results in improved production levels.

Nesting

With the Nesting facility in our planning system, material usage is maximized, and the components are arranged effectively with the raw materials. It is adapted to fabrication, cutting (sheets), textile, and woodworking industries, and minimizes the waste and the built-in mode of the ERP system.

Planning

Planning, as a component of the production planning module, enables demand forecasting, planning of material, and capital utilization. As a part of the enterprise management system, it guarantees effective schedules, optimal resource Planning, and reduction of downtimes within the system of planning in production.

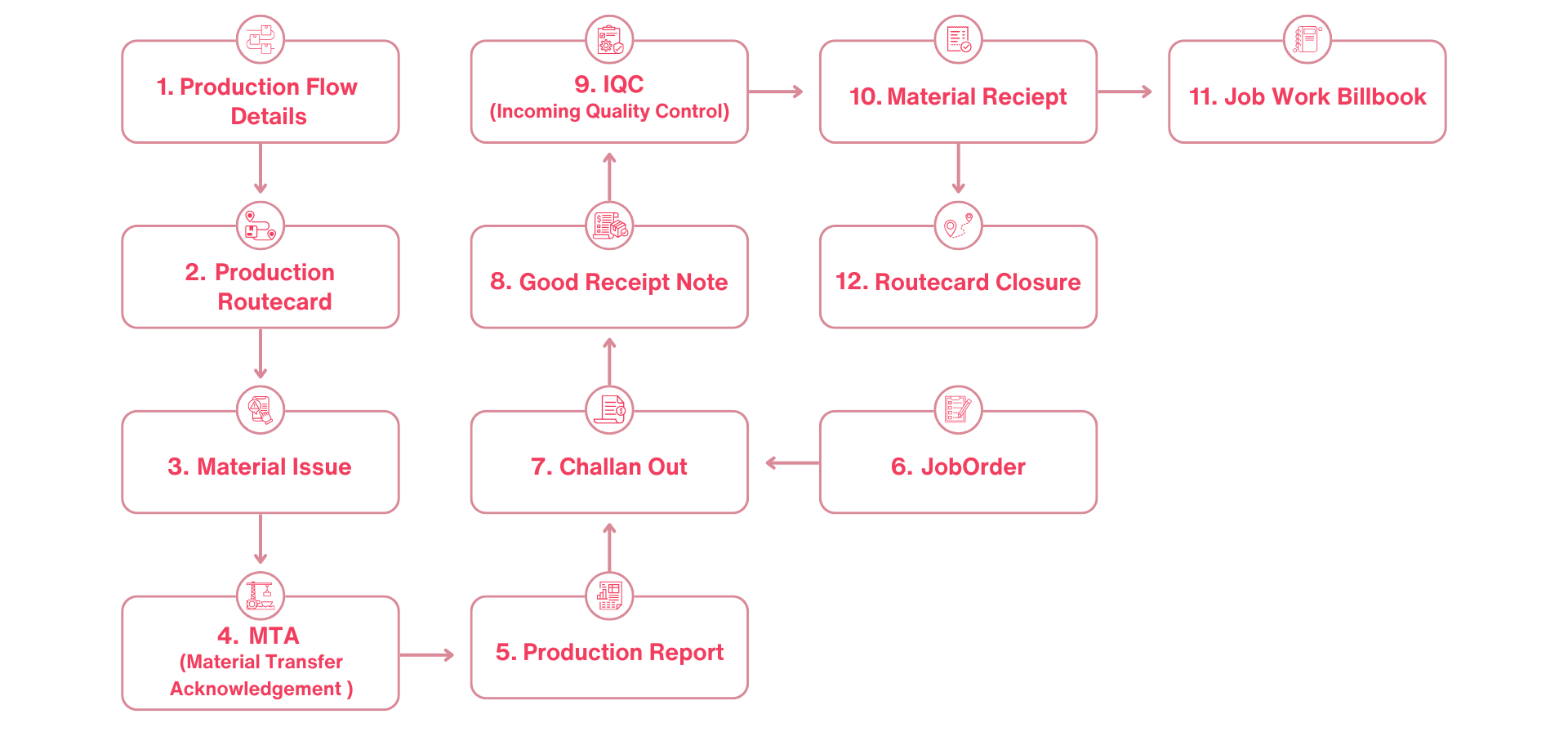

this is how production Management works