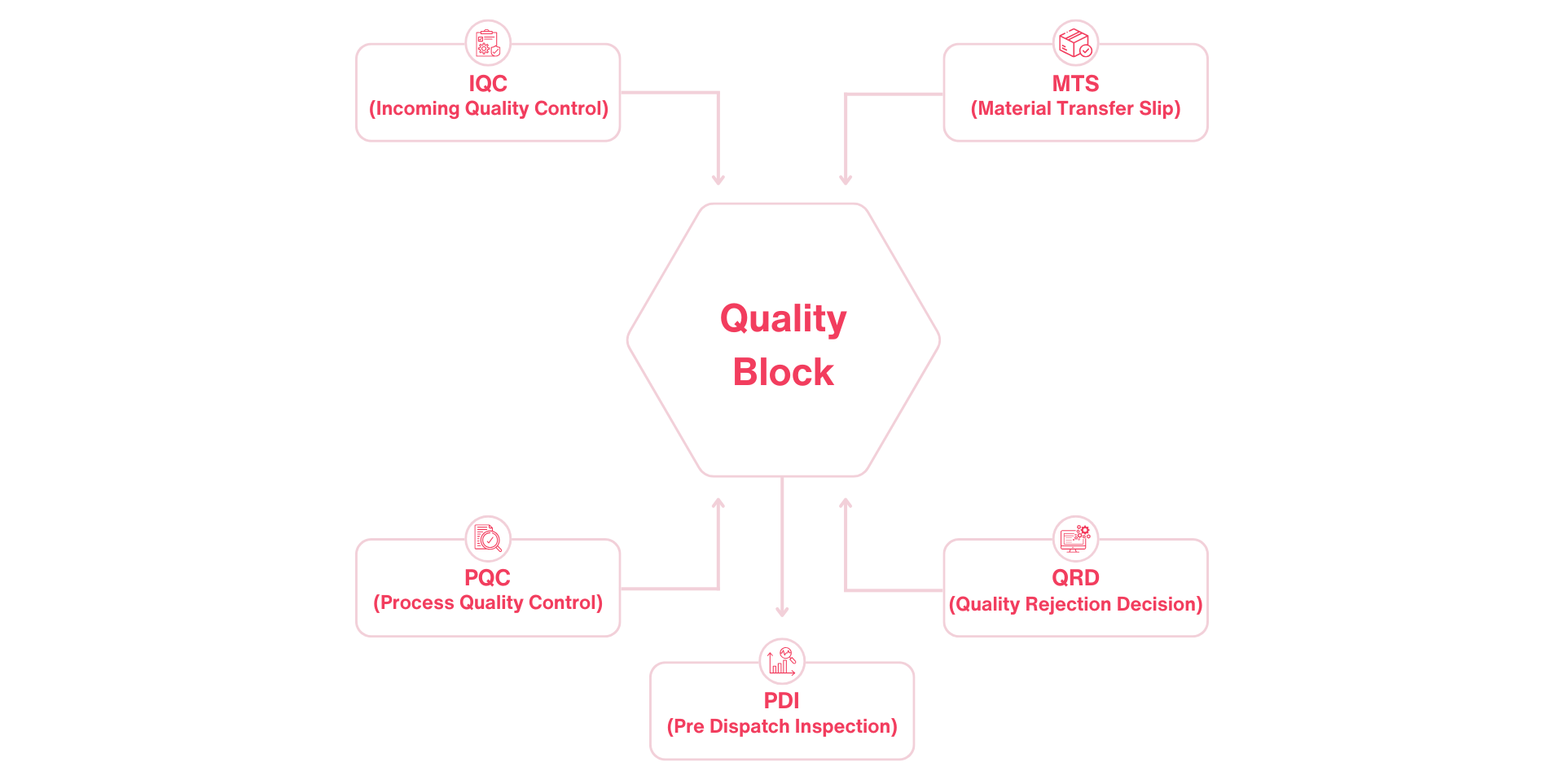

Quality Block

We can save your money and increase the quality of products with our Quality Block, which is integrated in our ERP and enterprise management system. We have a highly sophisticated quality control system that allows each of the production steps, all the way up to raw material receipt and final delivery, to be of the utmost standards. The quality block assists in reducing defects, enhances compliance, and provides high-quality products within an efficient production cycle to the customers.

Top brands that use our platform

What is Quality Block?

All the quality management processes using an ERP system, such as Hexbis Enterprise Management system, integrate all activities into a single interlocked quality control system known as the Quality Block. It allows manufacturing companies to monitor, control, and improve quality at every stage of their manufacturing and therefore meet industry regulations, minimize rework, and satisfy customers.

Key Features

Process Quality Control (PQC)

Perform quality services at each production point to detect and handle them early. Our quality block has the PQC feature that will maintain the standard of each product and integrates with your quality control system in the ERP system.

PDI - Pre-Dispatch Inspection

Conduct stringent checks prior to the shipping of goods to ascertain that the demands of the customers are being met to achieve customer satisfaction levels. This is a quality block feature that can be used to uphold the credibility of the products, and which is also captured in your enterprise management system.

Incoming Quality Control

Raw materials should be inspected and confirmed prior to being put into production. That way, the bad quality inputs do not halt manufacturing, and the process is totally absorbed in your ERP system.

Quality Compliant Reporting

Reporting at a granular level to countermand ISO, ASTM, and other related industry standards compliance. The quality block reports the compliance, and this simplifies the processes of undertaking the audit within the enterprise management system.

Rejection Handling & Quality Rework Management

Control defect components and reworking activities. The quality block follows rejections, assigns preventive measures, and contributes to updating the quality control system in your ERP system to produce goods of better quality.

this is how Quality Block works